130 Rubert Make Surface Roughness Comparator

MOQ : 1 Piece

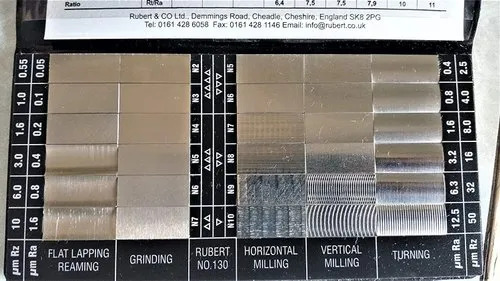

130 Rubert Make Surface Roughness Comparator Specification

- Application Media

- Metal Surface Testing

- Measurement Range

- 0.05m to 12.5m

- Equipment Type

- Surface Roughness Comparator

- Material

- Metal Plates

- No. of Scale Ranges

- 6 Types

- Finish Types

- Lapping, Reaming, Milling

- Sample Type

- Flat & Curved Surfaces

- Reusability

- Reusable

- Condition

- New Only

- Size

- Pocket Size

- Operation

- Manual

- Usage

- Laboratory, Industrial

- Plate Type

- Grinding, Turning, Milling

130 Rubert Make Surface Roughness Comparator Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About 130 Rubert Make Surface Roughness Comparator

Get the crowning solution for surface assessment with the 130 Rubert Make Surface Roughness Comparator! On Sale and ready to reserve, this splendiferous comparator is expertly crafted for manual operation with plate types suited to grinding, turning, and milling. Its first-string versatility accommodates both flat and curved surfaces, spanning six precision scale ranges and finish types like lapping, reaming, and milling. Compact pocket size, made with durable metal plates, it is ideal for laboratory and industrial use, ensuring reliable, reusable performance. Perfect for metal surface testing. Exporter, manufacturer, and supplier based in India.

Comprehensive Use & Application Surface

The 130 Rubert Make Surface Roughness Comparator is extensively used in laboratories and industrial environments to assess the finish of flat and curved metal surfaces. Ideal for quality control and metal testing, its versatility spans grinding, turning, and milling sample types. Whether for process calibration or research, this equipment supports various finish types, ensuring precise evaluation for first-string metalworking applications. Its compact, pocket-sized design enables easy carrying and convenient on-site usage.

Supply Ability, Certifications, and Sampling

With substantial market value, the 130 Rubert comparator is readily available for swift packing & dispatching to meet your operational demands. Our products are certified to industry standards, confirming their reliability and accuracy. Samples are available upon request, allowing you to evaluate performance before bulk purchase. Experience a seamless supply process with secure packing, prompt dispatching, and dependable after-sales service, reinforcing our position as a trusted supplier of laboratory equipment in India.

Comprehensive Use & Application Surface

The 130 Rubert Make Surface Roughness Comparator is extensively used in laboratories and industrial environments to assess the finish of flat and curved metal surfaces. Ideal for quality control and metal testing, its versatility spans grinding, turning, and milling sample types. Whether for process calibration or research, this equipment supports various finish types, ensuring precise evaluation for first-string metalworking applications. Its compact, pocket-sized design enables easy carrying and convenient on-site usage.

Supply Ability, Certifications, and Sampling

With substantial market value, the 130 Rubert comparator is readily available for swift packing & dispatching to meet your operational demands. Our products are certified to industry standards, confirming their reliability and accuracy. Samples are available upon request, allowing you to evaluate performance before bulk purchase. Experience a seamless supply process with secure packing, prompt dispatching, and dependable after-sales service, reinforcing our position as a trusted supplier of laboratory equipment in India.

FAQ's of 130 Rubert Make Surface Roughness Comparator:

Q: How is the 130 Rubert Make Surface Roughness Comparator used in industrial and laboratory settings?

A: The comparator is used to visually and physically compare the surface finish of metal samples against calibrated reference plates, ensuring process consistency in industrial and laboratory environments.Q: What are the types of surfaces that can be assessed with this comparator?

A: It is designed to test both flat and curved metal surfaces, covering a range of sample types like those produced by grinding, milling, and turning.Q: When can I expect the product to be dispatched after placing an order?

A: Products are typically packed and dispatched promptly upon confirmation of your order, ensuring minimal lead time and fast delivery.Q: Where does the 130 Rubert Comparator find its primary applications?

A: Its primary applications are in metal surface testing within laboratories and industries where precision surface finish is critical for quality assurance.Q: What is the measurement range of this surface roughness comparator?

A: The comparator measures surface roughness across a range of 0.05m to 12.5m, accommodating a broad spectrum of industrial requirements.Q: How does the sample availability process work?

A: Sample units can be reserved upon request, allowing potential buyers to evaluate the product performance in their specific applications before making a full-scale purchase.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Precision Measuring Instruments Category

Sf-500 Digital Force Gauge

Minimum Order Quantity : 1 Piece

Range : 500N / 50kg / 110Lb

Accuracy : +/0.5%

Equipment Type : Digital Force Gauge

Resolution : 0.1N / 0.01kg / 0.01Lb

Power Supply : 3.7V lithium Battery

Adjustable Outside Micrometers

Minimum Order Quantity : 1 Piece

Range : 25 50 mm

Accuracy : 0.002 mm

Equipment Type : Adjustable Outside Micrometer

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free