Ultrasonic Thickness Gauging Service

Ultrasonic Thickness Gauging Service Specification

- Testing Range

- 1 mm to 300 mm

- Operating Temperature

- -10°C to 50°C

- Applicable Surfaces

- Ferrous and Non-Ferrous Metals

- Usage

- Industrial

- Equipment Used

- Portable Digital Ultrasonic Gauge

- Reporting Time

- Within 24 Hours

- Accuracy

- ±0.01 mm

- Service Mode

- Offline

- Thickness Gauge Type

- Ultrasonic

- Surface Preparation

- Minimal Required

- Data Output

- Digital and Report Format

About Ultrasonic Thickness Gauging Service

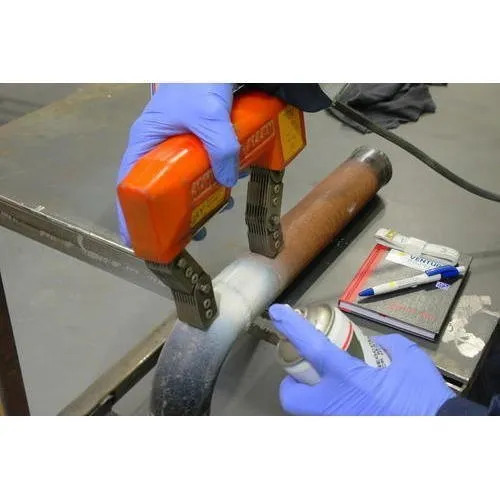

Experience peerless precision with our Ultrasonic Thickness Gauging Service-a virtuoso solution for evaluating both ferrous and non-ferrous metals. With an ephemeral turnaround (within 24 hours) and a remarkable accuracy of 0.01 mm, this service employs advanced portable digital ultrasonic gauges requiring minimal surface preparation. Usable in temperatures ranging from -10C to 50C, and covering a bold testing range of 1 mm to 300 mm, it's crafted for the industrial connoisseur. Take advantage of a markdown in price for limited-time offers. As a best-in-class exporter, manufacturer, supplier, and service provider in India, our digital reports empower you to make informed decisions.

Comprehensive Precision - Best for Industrial Surfaces

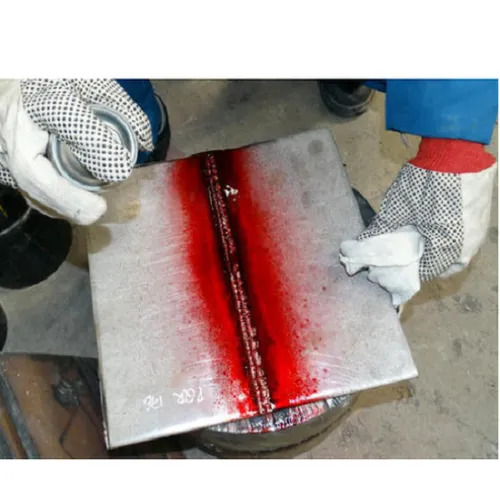

Our Ultrasonic Thickness Gauging Service is designed for peerless performance across a spectrum of ferrous and non-ferrous metals. With versatility for industrial usage, it accommodates surfaces with minimal preparation. The portable gauge delivers instantaneous, reliable digital results for maintenance, quality control, or compliance checks. Special features include an extensive 1 mm to 300 mm testing range and an enviable 0.01 mm accuracy-ensuring confident, data-backed insights every time.

Sample Policy, Packaging, and Capacity: Transparent and Efficient

Clients find our expenditure quotations transparent and fair. We provide clear sample policies upon request, and every report is carefully packaged to ensure security and confidentiality. Our robust supply system can fulfill bulk and repeat industrial demands, underlining our commitment to timely delivery. With this peerless supply ability, you can trust us for consistent, high-quality data output-helping you control costs while maintaining testing excellence.

Comprehensive Precision - Best for Industrial Surfaces

Our Ultrasonic Thickness Gauging Service is designed for peerless performance across a spectrum of ferrous and non-ferrous metals. With versatility for industrial usage, it accommodates surfaces with minimal preparation. The portable gauge delivers instantaneous, reliable digital results for maintenance, quality control, or compliance checks. Special features include an extensive 1 mm to 300 mm testing range and an enviable 0.01 mm accuracy-ensuring confident, data-backed insights every time.

Sample Policy, Packaging, and Capacity: Transparent and Efficient

Clients find our expenditure quotations transparent and fair. We provide clear sample policies upon request, and every report is carefully packaged to ensure security and confidentiality. Our robust supply system can fulfill bulk and repeat industrial demands, underlining our commitment to timely delivery. With this peerless supply ability, you can trust us for consistent, high-quality data output-helping you control costs while maintaining testing excellence.

FAQ's of Ultrasonic Thickness Gauging Service:

Q: How does the ultrasonic thickness gauging process work?

A: Ultrasonic thickness gauging employs sound waves transmitted through the metal surface to measure thickness accurately. The portable digital gauge captures reflections, converting them into precise thickness readings displayed digitally and provided in comprehensive reports.Q: What surfaces can the ultrasonic thickness gauging service assess?

A: Our service accurately evaluates both ferrous and non-ferrous metal surfaces, requiring minimal surface preparation. This makes it suitable for pipes, tanks, plates, and other industrial equipment.Q: When will I receive my thickness gauging report?

A: You will receive a complete digital report within 24 hours of the testing process, ensuring minimal downtime and prompt decision-making for your operations.Q: Where can this service be used most effectively?

A: The service excels in industrial settings, such as manufacturing plants, fabrication workshops, and maintenance sites-anywhere accurate thickness assessments of metallic surfaces are essential.Q: What are the main benefits of using your ultrasonic thickness gauging service?

A: Key benefits include a wide testing range (1 mm to 300 mm), exceptional accuracy (0.01 mm), rapid turnaround, minimal surface preparation, and compatibility with various metals-all at competitive prices.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry