Magnetic Particle Testing Services

Price 2000 INR/ Piece

MOQ : 1 Piece

Magnetic Particle Testing Services Specification

- Usage/Application

- Industrial

- Standards Followed

- ASME, ASTM, IS, ISO

- Product Type

- Magnetic Particle Testing Services

- Operator Qualification

- Certified NDT Level II/III Personnel

- Technique

- Magnetic Particle Inspection

- Testing Type

- Welded Joint, Forgings, Castings, Pipes, Structures

- Maximum Component Size

- Customizable as Per Client Requirement

- Reporting Time

- Within 2-5 Working Days

- Service Type

- Non-Destructive Testing

- Mode Of Report

- Soft Copy, Hard Copy

- Applicable Materials

- Ferromagnetic Materials

- Service Mode

- Offline

- Equipment Used

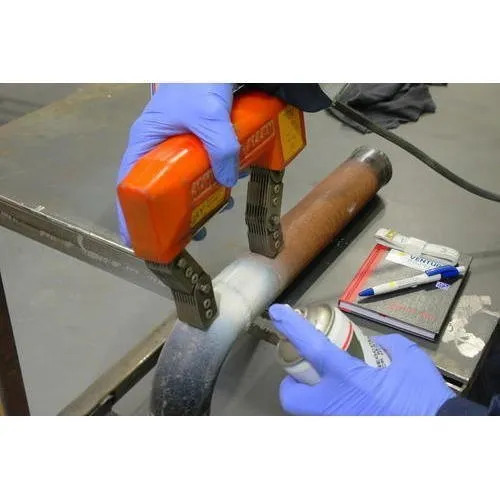

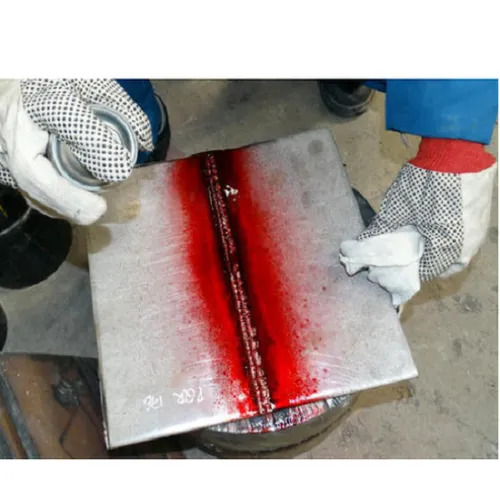

- Yoke, Prod, Coil, Wet and Dry Powders, Fluorescent Inks

- Location

- All Over India

- Service Duration

- Depends on Job Size and Complexity

- Detection Capability

- Surface and Slightly Subsurface Discontinuities

Magnetic Particle Testing Services Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Magnetic Particle Testing Services

Magnetic Particle Testing Services have become a popular choice for industries aiming to grab exceptional detection results at a remarkable bargain. Our expert team utilizes advanced equipment such as yoke, prod, coil, dry and wet powders, and fluorescent inks to ensure marvelous accuracy in identifying surface and slightly subsurface discontinuities in ferromagnetic materials. Enlightened by certified Level II/III NDT personnel, we strictly adhere to top global standards (ASME, ASTM, IS, ISO). Reports are delivered within 2-5 working days. Service is customizable for any component size across India. Ideal for welded joints, castings, forgings, and industrial structures.

Targeted Application & Advanced Features for Superior Testing

Magnetic Particle Testing Services are designed for specific and general industrial use, effectively identifying flaws on surface and slightly subsurface levels. The method is broadly applicable on welded joints, castings, pipes, forgings, and structural components crafted from ferromagnetic materials. Featuring state-of-the-art machines-yoke, prod, coil-and a selection between wet or dry powders with fluorescent inks, these services ensure meticulous flaw detection. Applied on surfaces, the process guarantees thoroughness and reliability in industrial inspections.

FOB Port, Sample Policy, and Professional Certifications

Our Magnetic Particle Testing Services can be shipped from major FOB ports across India, ensuring secure packaging and efficient packing & dispatch processes. Sample policies are tailored per client requirements, providing flexibility and trust. Every service is managed by certified Level II/III NDT personnel and complies with international certifications like ASME, ASTM, IS, and ISO standards. This professional backing guarantees that each inspection meets rigorous quality and safety measures, from packaging to delivery.

Targeted Application & Advanced Features for Superior Testing

Magnetic Particle Testing Services are designed for specific and general industrial use, effectively identifying flaws on surface and slightly subsurface levels. The method is broadly applicable on welded joints, castings, pipes, forgings, and structural components crafted from ferromagnetic materials. Featuring state-of-the-art machines-yoke, prod, coil-and a selection between wet or dry powders with fluorescent inks, these services ensure meticulous flaw detection. Applied on surfaces, the process guarantees thoroughness and reliability in industrial inspections.

FOB Port, Sample Policy, and Professional Certifications

Our Magnetic Particle Testing Services can be shipped from major FOB ports across India, ensuring secure packaging and efficient packing & dispatch processes. Sample policies are tailored per client requirements, providing flexibility and trust. Every service is managed by certified Level II/III NDT personnel and complies with international certifications like ASME, ASTM, IS, and ISO standards. This professional backing guarantees that each inspection meets rigorous quality and safety measures, from packaging to delivery.

FAQ's of Magnetic Particle Testing Services:

Q: How does the Magnetic Particle Testing process work for surface and subsurface discontinuities?

A: The process involves magnetizing the area under inspection, then applying magnetic particles (wet or dry powder, or fluorescent ink) to the surface. Any surface or slightly subsurface discontinuities will disrupt the magnetic field, causing particles to collect at the defect site, making them visible under proper lighting.Q: What materials are suitable for Magnetic Particle Testing Services?

A: This testing method is specifically applicable to ferromagnetic materials such as iron, steel, and their alloys. It is commonly utilized on welded joints, forgings, castings, pipes, and industrial structures.Q: When can I expect the test reports to be delivered?

A: Reports are typically prepared and delivered within 2-5 working days after completion of the testing. Both soft and hard copy report formats are available to suit your requirement.Q: Where can these magnetic particle testing services be utilized?

A: Our services are available all over India and are widely adopted in sectors like construction, manufacturing, energy, and infrastructure for industrial components and welded structures.Q: What are the advantages of using certified NDT Level II/III personnel for this testing?

A: Certified Level II/III personnel bring advanced expertise and adherence to international standards, resulting in more accurate testing, reliable defect identification, and compliance with quality regulations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry