DAC Ultrasonic Calibration Block

MOQ : 1 Piece

DAC Ultrasonic Calibration Block Specification

- Application

- DAC Ultrasonic Calibration

- Features

- Ulatrsonic Flaw detector Calibration for DAC

- Equipment Type

- Ultrasonic Calibration Block

- Usage

- Calibration block

- Shape

- Rectangle

- Surface Finishing

- Smooth finish or Nickel Plating

- Specimen Size

- Customizable as required

- Length

- As per Standard

- Dimension

- As per Standard

- Block Type

- DAC type

- Material

- C.S/S.S/ As per Client Requirment

- Thickness

- 19, 38 etc

- Finish

- Smooth/Nickel plated

- Color

- Silver

- Packaging Type

- Standard

DAC Ultrasonic Calibration Block Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About DAC Ultrasonic Calibration Block

Discover the acclaimed DAC Ultrasonic Calibration Block, famed among industry professionals for its prodigious accuracy and robust construction. Manufactured as per global standards, this in-demand, rectangular silver block features a smooth or nickel-plated finish with customizable dimensions and thickness (19, 38 mm, and more). Its unparalleled performance makes it the preferred choice for ultrasonic flaw detector calibration for DAC applications. Made from premium C.S, S.S, or client-specific materials, it ensures reliability and durability. Trusted by exporters, manufacturers, and service providers throughout India. Add to Cart now for assured quality!

Versatile Usage and Application Scope

The DAC Ultrasonic Calibration Block is utilized as a reference standard for calibrating ultrasonic flaw detectors, playing a vital role in ensuring inspection accuracy. Primarily used in industrial and laboratory settings, it assists technicians in evaluating the sensitivity and performance of DAC setups. Its robust design and customizable specifications make it an essential tool for manufacturers, quality control teams, and service providers across the spectrum of ultrasonic testing.

Sample Availability, Order Processing & Supply Logistics

Samples of the DAC Ultrasonic Calibration Block are available to help clients assess quality prior to full order placement. Our efficient order processing system ensures timely Packing & Dispatch, meeting the stipulated list price and delivery parameters. With ample supply ability, we ship through major FOB ports across India, guaranteeing reliable logistics and seamless global distribution for large or small orders. Experience a smooth procurement process with dedicated support at every stage.

Versatile Usage and Application Scope

The DAC Ultrasonic Calibration Block is utilized as a reference standard for calibrating ultrasonic flaw detectors, playing a vital role in ensuring inspection accuracy. Primarily used in industrial and laboratory settings, it assists technicians in evaluating the sensitivity and performance of DAC setups. Its robust design and customizable specifications make it an essential tool for manufacturers, quality control teams, and service providers across the spectrum of ultrasonic testing.

Sample Availability, Order Processing & Supply Logistics

Samples of the DAC Ultrasonic Calibration Block are available to help clients assess quality prior to full order placement. Our efficient order processing system ensures timely Packing & Dispatch, meeting the stipulated list price and delivery parameters. With ample supply ability, we ship through major FOB ports across India, guaranteeing reliable logistics and seamless global distribution for large or small orders. Experience a smooth procurement process with dedicated support at every stage.

FAQ's of DAC Ultrasonic Calibration Block:

Q: How is the DAC Ultrasonic Calibration Block used in practice?

A: The DAC Ultrasonic Calibration Block is primarily used to calibrate ultrasonic flaw detectors in DAC (Distance Amplitude Correction) applications. Technicians use it as a reference standard during equipment setup and routine inspections to ensure accurate flaw detection and equipment sensitivity.Q: What materials are available for the calibration block?

A: The calibration block can be manufactured from carbon steel (C.S), stainless steel (S.S), or other materials as per the client's requirement. This flexibility allows the block to match specific inspection conditions and standards.Q: When should I request a sample before a full order?

A: Requesting a sample is advisable when you need to verify the block's quality, finish, and compatibility with your ultrasonic testing equipment before proceeding with a bulk or customized order. It helps ensure the product fully meets your technical requirements.Q: Where are DAC Ultrasonic Calibration Blocks commonly applied?

A: These blocks are widely employed in nondestructive testing environments such as manufacturing plants, quality assurance labs, and service centers where ultrasonic flaw detection systems need precise calibration for reliable results.Q: What is the packing and dispatch process for these calibration blocks?

A: Each DAC Ultrasonic Calibration Block undergoes a careful packing process using standard packaging materials to prevent damage. Orders are processed efficiently, and prompt dispatch is arranged via major FOB ports to ensure quick and secure delivery.Q: What are the benefits of using a DAC type ultrasonic calibration block?

A: Using a DAC type calibration block guarantees unparalleled accuracy in flaw detection, streamlined compliance with international testing standards, and extended durability, making it highly regarded among quality assurance professionals.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ultrasonic Calibration Blocks Category

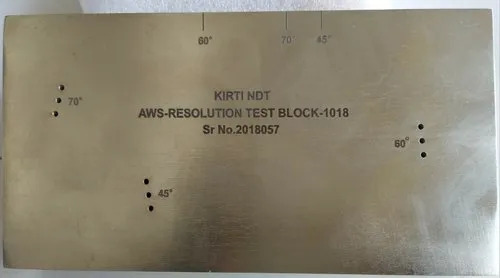

Resolution Ultrasonic Calibration Block

Minimum Order Quantity : 1 Piece

Features : Machine smooth finish or Nickel plated, Rectangle shape, Accurate dimensions

Application : For ultrasonic flaw detector calibration

Specimen Size : mm/Inch

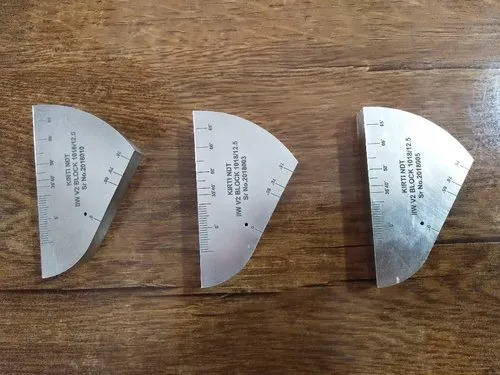

V2 Ultrasonic Calibration Block

Minimum Order Quantity : 1 Piece

Features : Ulatrsonic Flaw detector Calibration

Application : Ultrasonic flaw detector calibration

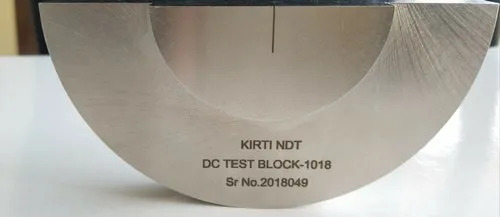

DC Ultrasonic Calibration Block

Minimum Order Quantity : 1 Piece

Application : Ultrasonic Testing Calibration

Specimen Size : 200 mm

V1 Ultrasonic Calibration Block

Minimum Order Quantity : 1 Piece

Features : Ulatrsonic Flaw detector Calibration

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free