Dye Penetrant Testing Services

Price 2000 INR/ Piece

MOQ : 1 Piece

Dye Penetrant Testing Services Specification

- Result Interpretation

- Visual or under UV light

- Inspection Method

- Visible and fluorescent dye

- Service Duration

- 1-2 Days

- Testing Standard

- ASTM E1417 or equivalent

- Accessibility

- Onsite and laboratory testing available

- Technique

- Dye Penetrant Testing

- Penetrant Sensitivity Level

- Level 1 to Level 4

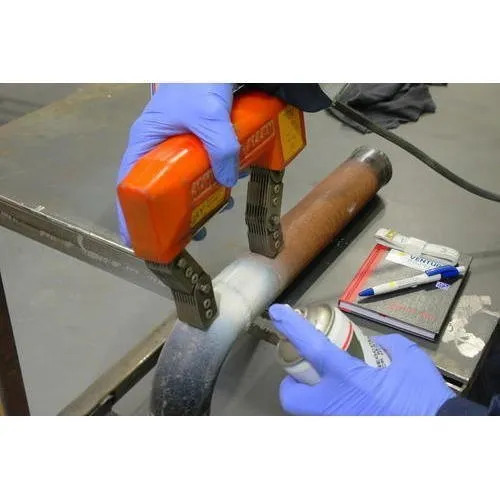

- Equipment Used

- Spray cans, UV lamps, developer powder

- Industries Served

- Automotive, Aerospace, Petrochemical, Power, Fabrication

- Application

- Surface Crack Detection

- Reporting Time

- Within 24 hours after test completion

- Service Mode

- Offline

- Surface Preparation

- Cleaning, Drying, Application of Penetrant

- Suitable Materials

- Metals, plastics, ceramics (non-porous only)

- Service Location/City

- Pan India

Dye Penetrant Testing Services Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Dye Penetrant Testing Services

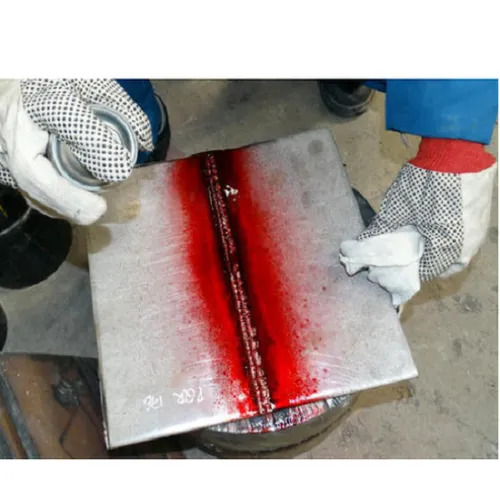

Experience splendiferous precision with our acclaimed Dye Penetrant Testing Services, designed for surface crack detection across automotive, aerospace, petrochemical, power, and fabrication sectors. Our potent, dazzling methods utilize visible and fluorescent dyes, ensuring reliable results on metals, plastics, and ceramics (non-porous only), all adhering to ASTM E1417 standards or equivalent. We offer competitive pricing and advance purchase options for both onsite and laboratory inspections pan India. Utilizing spray cans, UV lamps, and developer powder, we guarantee detailed reports within 24 hours after test completion, establishing ourselves as a leading exporter, manufacturer, service provider, and supplier in the inspection industry.

Suitable Applications & Versatile Media

Our Dye Penetrant Testing Services are suitable for general and specific uses, effectively detecting surface cracks in non-porous metals, ceramics, and plastics. With application media ranging from spray cans to developer powders, the process is adaptable for both industrial and field environments. Whether for general maintenance or critical component inspection, our solutions deliver rapid, reliable, and clear results, ensuring structural integrity and safety across a multitude of sectors.

Domestic Market Reach & Logistics Excellence

Serving the vast Indian domestic market, we offer quick dispatch of shipped goods from our designated FOB port. Our sample policy is transparent and crafted for customer ease, ensuring you experience optimal market value with every order. Prompt service and efficient logistics are at the heart of our offerings, affirming our commitment to timely delivery and customer satisfaction throughout the Pan India region.

Suitable Applications & Versatile Media

Our Dye Penetrant Testing Services are suitable for general and specific uses, effectively detecting surface cracks in non-porous metals, ceramics, and plastics. With application media ranging from spray cans to developer powders, the process is adaptable for both industrial and field environments. Whether for general maintenance or critical component inspection, our solutions deliver rapid, reliable, and clear results, ensuring structural integrity and safety across a multitude of sectors.

Domestic Market Reach & Logistics Excellence

Serving the vast Indian domestic market, we offer quick dispatch of shipped goods from our designated FOB port. Our sample policy is transparent and crafted for customer ease, ensuring you experience optimal market value with every order. Prompt service and efficient logistics are at the heart of our offerings, affirming our commitment to timely delivery and customer satisfaction throughout the Pan India region.

FAQ's of Dye Penetrant Testing Services:

Q: How does the Dye Penetrant Testing process work?

A: The process involves cleaning and drying the surface, applying a visible or fluorescent dye penetrant, removing excess dye, applying a developer, and then interpreting the results visually or under UV light to detect surface cracks.Q: What materials are suitable for Dye Penetrant Testing?

A: This method is effective for metals, plastics, and ceramics, provided they are non-porous. It is not recommended for porous materials, as the penetrant may absorb and skew results.Q: When can I expect the test results after completion?

A: You will receive a detailed report within 24 hours after the completion of the Dye Penetrant Testing, ensuring prompt and reliable feedback for your inspection needs.Q: Where can the testing be conducted?

A: Our services are available both onsite at your facility and in our fully-equipped laboratories, offering flexibility based on your operational requirements.Q: What are the primary benefits of using Dye Penetrant Testing?

A: This inspection method offers potent sensitivity, quick turnaround time, and dazzling clarity in detecting surface cracks, thus enhancing maintenance regimes and operational safety across diverse industries.Q: What standards are followed during the inspection?

A: All our Dye Penetrant Testing Services are performed following ASTM E1417 or equivalent standards, ensuring the highest compliance, reliability, and accuracy.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free