Ultrasonic Testing Services

Ultrasonic Testing Services Specification

- Frequency Range

- 0.5 MHz to 10 MHz

- Application/Usage

- Industrial

- Suitable For

- Welds, castings, forgings, pipelines, and structural materials

- Operator Qualification

- Level II / Level III certified professionals

- Minimum Order Quantity

- 1 Job

- Service Location/City

- Pan India

- Turnaround Time

- Fast and reliable results within committed schedules

- Detection Capability

- Flaws such as cracks, inclusions, voids, laminations

- Testing Standard

- As per ASTM, IS, and ASME standards

- Service Type

- Ultrasonic Testing Services

- Equipment Used

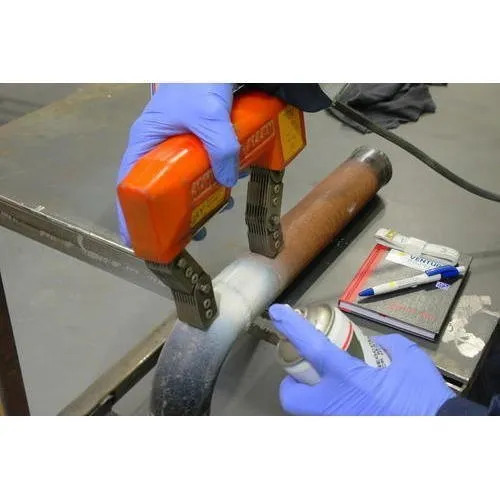

- Portable digital ultrasonic flaw detectors

- Testing Type

- Non-Destructive Testing (NDT)

- Reporting

- Detailed inspection and test result documentation

- Technique Used

- Pulse-echo and Through Transmission

- Service Mode

- Offline

About Ultrasonic Testing Services

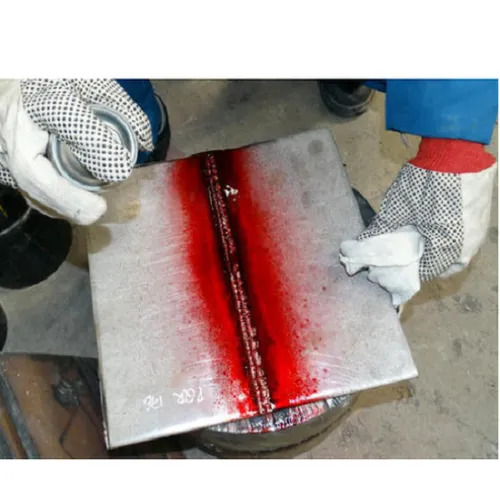

Experience elite ultrasonic testing services-available for a limited time with instant checkout options! Our exquisite solutions utilize both pulse-echo and through transmission techniques, suitable for welds, castings, forgings, pipelines, and structural materials. Revealing hidden flaws such as cracks, inclusions, voids, and laminations, our NDT reporting is remarked for its thoroughness and accuracy. All inspections adhere to ASTM, IS, and ASME standards, powered by advanced portable flaw detectors. Sizzling fast turnaround with Level II and Level III experts ensures reliability. Minimum order: one job. Pan India service.

Comprehensive Industrial Ultrasonic Testing Applications

Ultrasonic Testing Services are specifically used to assess the integrity of welds, castings, forgings, pipelines, and various structural materials. Utilizing sophisticated pulse-echo and through transmission methods, the technique is ideal for detecting subsurface defects. Widely applied in industrial environments, these services help manufacturers and exporters maintain stringent quality control across plants and facilities, ensuring equipment remains reliable and operational.

Certified Results and Rapid Delivery Process

With operators certified at Level II and Level III, our ultrasonic testing adheres strictly to top industry standards. We maintain a transparent sample policy, enabling easy drop-off and pickup options. Ready stock ensures quick scheduling, while express shipping guarantees timely execution of each job. Our remarkable supply ability and nationwide reach signify rapid order fulfillment, keeping production lines on track with assured quality and detailed reports.

Comprehensive Industrial Ultrasonic Testing Applications

Ultrasonic Testing Services are specifically used to assess the integrity of welds, castings, forgings, pipelines, and various structural materials. Utilizing sophisticated pulse-echo and through transmission methods, the technique is ideal for detecting subsurface defects. Widely applied in industrial environments, these services help manufacturers and exporters maintain stringent quality control across plants and facilities, ensuring equipment remains reliable and operational.

Certified Results and Rapid Delivery Process

With operators certified at Level II and Level III, our ultrasonic testing adheres strictly to top industry standards. We maintain a transparent sample policy, enabling easy drop-off and pickup options. Ready stock ensures quick scheduling, while express shipping guarantees timely execution of each job. Our remarkable supply ability and nationwide reach signify rapid order fulfillment, keeping production lines on track with assured quality and detailed reports.

FAQ's of Ultrasonic Testing Services:

Q: How does the ultrasonic testing process detect flaws in industrial materials?

A: Ultrasonic testing uses high-frequency sound waves to penetrate materials such as welds, castings, and pipelines. By analyzing the reflected signals through pulse-echo and through transmission techniques, our experienced professionals can detect hidden flaws like cracks, voids, and laminations without causing any damage to the tested items.Q: What applications are best suited for ultrasonic testing services?

A: Ultrasonic testing is best suited for industrial applications involving welds, castings, forgings, pipelines, and structural materials where internal quality verification is required. It is widely used by manufacturers, exporters, suppliers, and service providers across various sectors to ensure product reliability and compliance with industry standards.Q: Where can I avail these ultrasonic testing services in India?

A: Our ultrasonic testing services are available pan India. We operate in major industrial cities and regions, ensuring rapid, on-site inspection and detailed reporting wherever your facility or project is located.Q: What is the typical turnaround time for receiving inspection results?

A: We offer fast and reliable turnaround, providing detailed inspection results and documentation within committed schedules. Expedited processing is available to meet urgent project requirements without compromising report accuracy.Q: Who performs the testing and what are their qualifications?

A: Testing is conducted by Level II and Level III certified professionals, who are qualified to the latest ASTM, IS, and ASME standards. Their expertise ensures precise flaw detection and compliance with all regulatory requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free