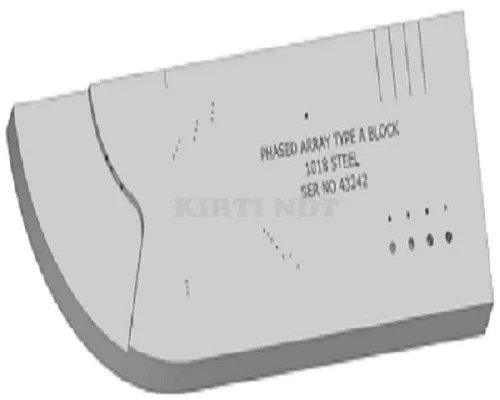

Phased Array Calibration

Phased Array Calibration Specification

- Features

- Ulatrsonic Flaw detector Calibration

- Surface Finishing

- Machine smooth finish or NIckel plated

- Finish

- High-precision

- Size/Dimension

- mm/Inch

- Specimen Size

- Customizable

- Material

- c.s/ss

- Testing

- Phased array ultrasonic

- Color

- Silver

- Length

- As per Standard

- Equipment Type

- Calibration block

- Application

- Phased array probe setup

- Usage

- Non-destructive testing

Phased Array Calibration Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Phased Array Calibration

Phased Array Calibration: Commercial Versatility and Advanced Features

Our phased array calibration blocks offer a practical solution for non-destructive testing across diverse commercial sectors. Featuring customizable specimen sizes, these blocks facilitate precise calibration for phased array probes, ensuring meritorious results in ultrasonic flaw detection. Superior machine-smooth or nickel-plated finishes enhance their durability and accuracy. They are indispensable for quality assurance in industries such as aerospace, automotive, and manufacturing, providing reliable setup for high-demand, critical inspections.

FOB Port, Supply Capability, and Swift Export Delivery

We handover each calibration block through major Indian FOB ports, assuring secure global transfer. With a robust supply ability and streamlined logistics, we guarantee quick dispatch and punctual delivery tailored to your needs. Our main export markets include Asia, Europe, and North America, establishing us as a trusted exporter. Clients benefit from our efficient process, receiving calibration solutions promptly-maximizing uptime and operational efficiency in their phased array ultrasonic testing workflows.

FAQ's of Phased Array Calibration:

Q: How is the phased array calibration block used in non-destructive testing?

A: The calibration block is utilized to calibrate ultrasonic flaw detectors, ensuring accurate and reliable phased array probe setup for non-destructive testing applications.Q: What materials are available for the calibration block construction?

A: Customers can select from carbon steel (c.s) or stainless steel (ss), depending on their testing requirements and industry standards.Q: Where can these calibration blocks be delivered for export orders?

A: We export globally, handing over products through prominent Indian FOB ports, reaching key markets in Asia, Europe, and North America.Q: What is the typical process for ordering a custom-sized calibration block?

A: Clients can specify dimensions in mm or inches, and select surface finishing options. We ensure rapid production, quick dispatch, and timely delivery to meet operational schedules.Q: What extra features do the calibration blocks offer for commercial clients?

A: They feature high-precision finishing (machine-smooth or nickel plated), are suitable for phased array probe setup, and provide certified accuracy for ultrasonic flaw detector calibration tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ultrasonic Calibration Blocks Category

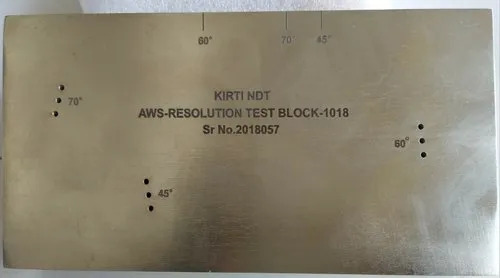

Resolution Ultrasonic Calibration Block

Minimum Order Quantity : 1 Piece

Features : Machine smooth finish or Nickel plated, Rectangle shape, Accurate dimensions

Application : For ultrasonic flaw detector calibration

Specimen Size : mm/Inch

Capacity : Varies as per standard

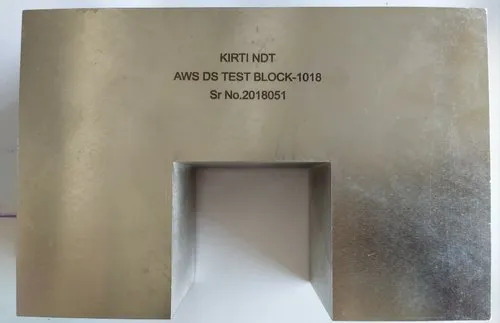

DSC Ultrasonic Calibration Block

Minimum Order Quantity : 1 Piece

Features : Ulatrsonic Flaw detector Calibration

Application : Calibration of ultrasonic flaw detectors

Specimen Size : As per Standard or customer

Capacity : As per Standard

Step Wedge Ultrasonic Calibration Block

Minimum Order Quantity : 1 Piece

Features : Ultrasonic Linear Calibration

Application : Ultrasonic Flaw Detector Calibration

DS Ultrasonic Calibration Block

Minimum Order Quantity : 1 Piece

Features : Ulatrsonic Flaw detector Calibration

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free